Tape Winding utilizes the same machine technology as Laser-assisted Tape Placement (LATP) and can thus be referred to as Laser-assisted Tape Winding (LATW). Unlike LATP, the UD tape is placed onto a spinning mandrel, which serves as the winding core, rather than a flat mold. Alternatively, the tape can be wound directly onto a plastic liner. The winding angle can be adjusted by altering the rotational movement of the mandrel and the translational movement of the tape-applying robot system. Tape Winding allows for the manufacture of rotationally symmetric components such as tubes, pipes, bearings and even pressure vessels.

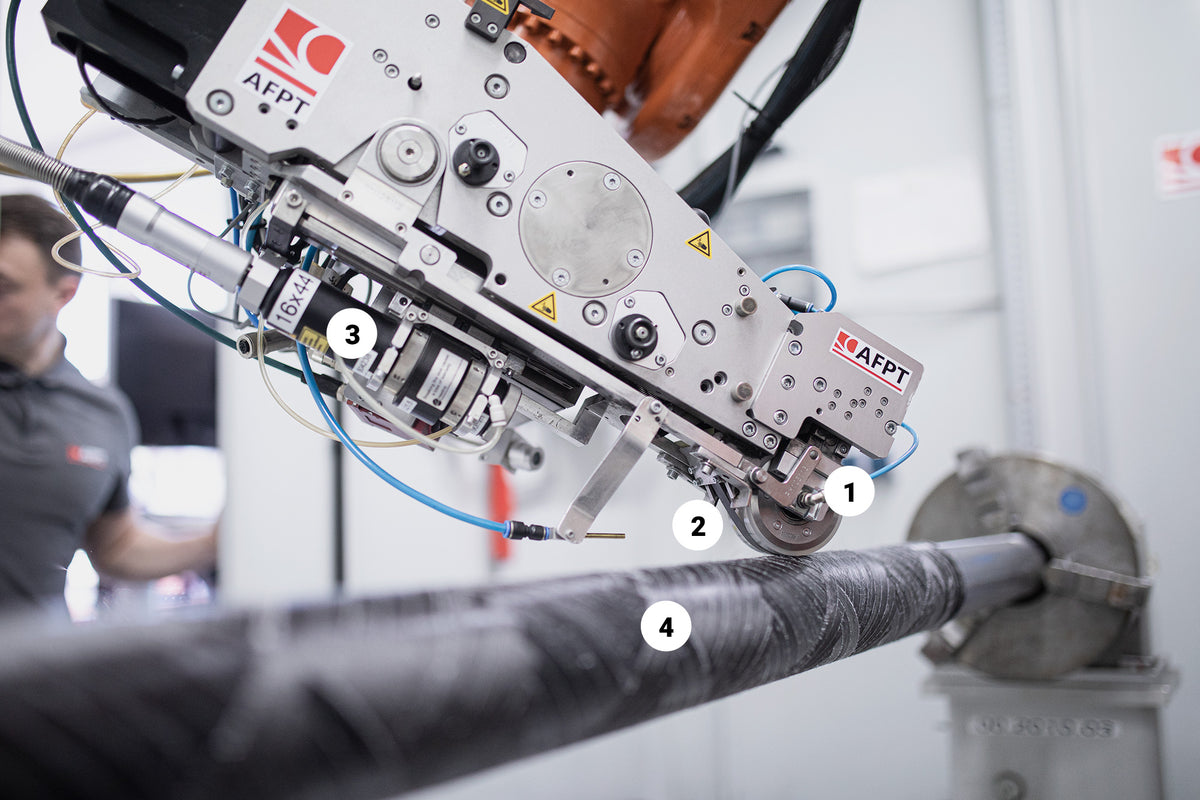

The UD tape material (typically 12 or 25 mm wide) is unwound and transported to the tip of the placement head (2). At this point, the laser system (3) locally heats the tape above its melting point. Immediately after heating, the tape is placed onto the spinning mandrel, liner or substrate (4) using the pressure-applying consolidation roller (1). All process parameters are logged for quality assurance purposes.

Discover the automated precision behind the Tape Winding process. Watch the video to see the process in action and witness how TAFNEX™ UD Tape is transformed into high-quality TAFNEX™ Tubes.