The initial processing step for each TAFNEX™ Sheet varies. For TAFNEX™ Structural Sheets, the process begins by stacking individual layers of UD tape according to the desired layer structure, with the option to fix these layers. TAFNEX™ Woven Sheet involves weaving the UD tape together on specialized weaving machines to achieve the desired pattern. The most complex initial step is for the TAFNEX™ Design Sheet, which requires evenly scattering and optionally fixing the chips. These different structures are then consolidated in a press. This second step is also used to produce TAFNEX™ Sandwich Panels by bonding the skin and core layers through consolidation. Learn more about the consolidation process below.

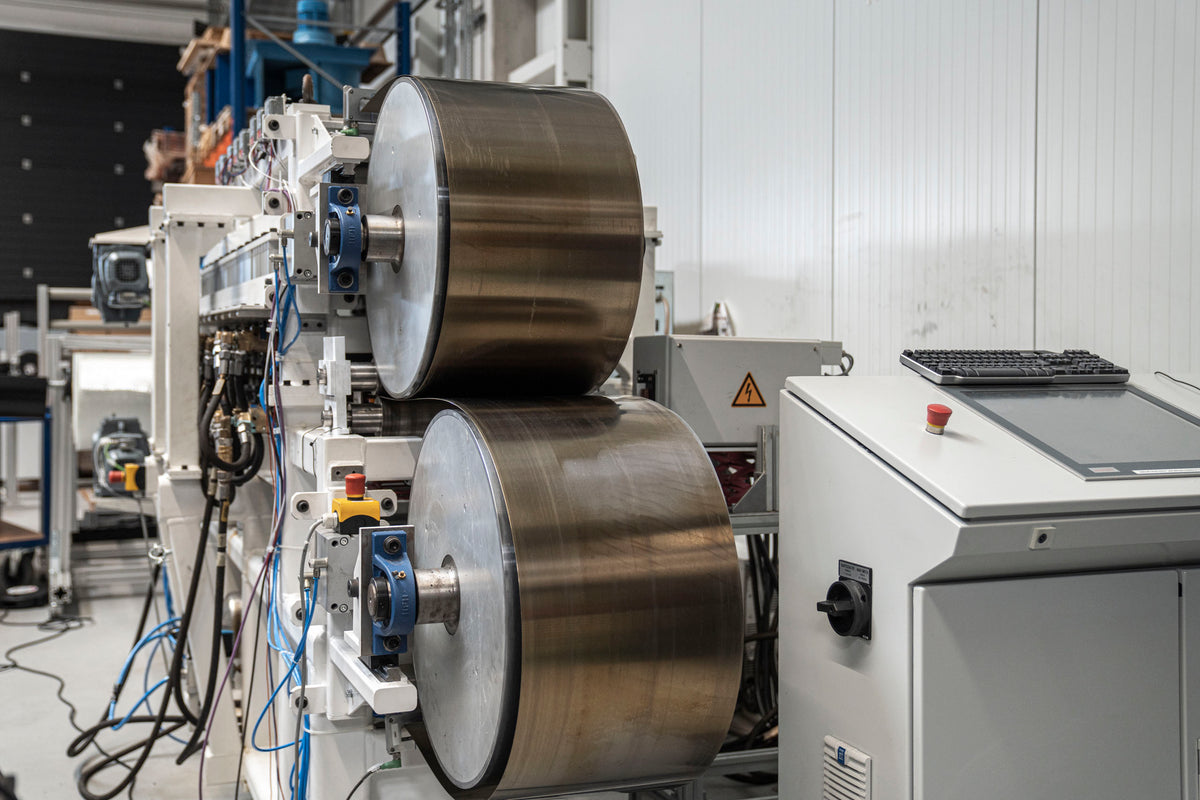

Various machine technologies are available for sheet consolidation, each differing in maximum machine throughput. While discontinuous or semi-continuous processes are typically employed for TAFNEX™ Sheets, the continuous double belt process is commonly used for producing TAFNEX™ Sandwich Panels or high-volume production of TAFNEX™ Sheets. For TAFNEX™ Design Sheets, it is possible to integrate the scattering of chips into semi-continuous or continuous consolidation machinery.

As discontinuous consolidation with a hot press is by far the most common, it is described below with the example of producing a TAFNEX™ Structural Sheet.

1. Prepare tape stack

2. Heat up press

3. Insert tape stack into press/mold

4. Close press/mold

5. Apply pressure

6. Cool down (after certain holding time)

7. Optional: Reduce pressure at certain temperature level

8. Open press/mold when demolding temperature is reached

9. Demold TAFNEX™ Structural Sheet