Sandwich Panels consist of a skin and a core, each serving distinct functions. TAFNEX™ Sandwich Panels, typically featuring a skin and core made of the same polymer (PP), are easily recyclable. They are often used as flat panels but can also be processed through Thermoforming, Compression Molding or Injection Molding. Discover more below.

Following nature's lead, honeycomb cores have a storied history in aerospace and maritime applications, distinguished by their impressive strength-to-weight ratio. Although traditional aluminum and paper-based cores continue to be utilized, there is a growing trend towards the adoption of polymer-based cores.

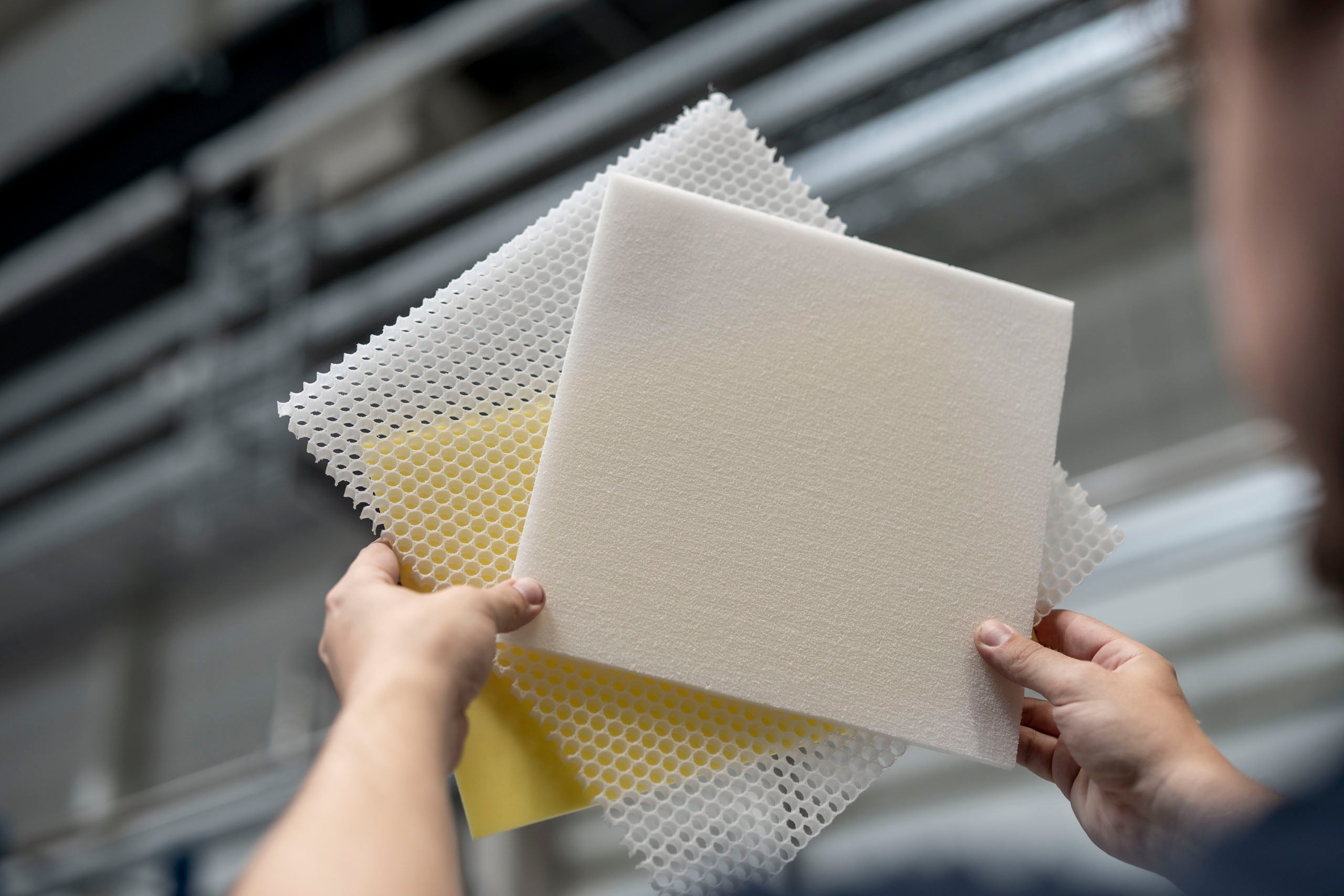

Traditionally, honeycombs are constructed using hexagonal shapes. In contrast, tubular honeycombs are fabricated from circular cylinders, enabling them to withstand forces from multiple directions while preserving their form. The isotropic mechanical properties of these individual cells contribute significantly to the overall stability of the honeycomb plate, and consequently, the final product.

Although the compression strength of foam cores may be marginally lower than that of honeycomb cores, they provide superior thermal and acoustic insulation. Furthermore, they are less likely to cause surface marks.

Apart from the standard honeycomb and foam cores, there are other specialized core materials available on the market. A notable example is the textile-reinforced polypropylene foam core material by Lighterials, tailored for microsandwich uses.

Also, a very high-performance sandwich structure can be realized by using a PP-GF LFT core.

TAFNEX™ Sandwich Panels, typically deployed as flat sheets, can also be converted into three-dimensional components. The process of bonding the skin and core may also be performed at this processing stage, particularly when employing foam cores.