Tape Placement, also known as Automated Fiber Placement (AFP), is an advanced technique for producing composite parts or preforms from UD tapes like TAFNEX™. The slit tapes are placed individually, resulting in low-waste, load-optimized tailored blanks or local reinforcements. Various technologies from different machine manufacturers are available. Some systems use local spot-welding to fix the tape stack, which then requires consolidation in a subsequent process. However, more common are robot-based systems that include in-situ consolidation during placement. These systems use laser technology to locally melt the UD tape and are sometimes referred to as Laser-assisted Tape Placement (LATP). The following discussion will focus on LATP.

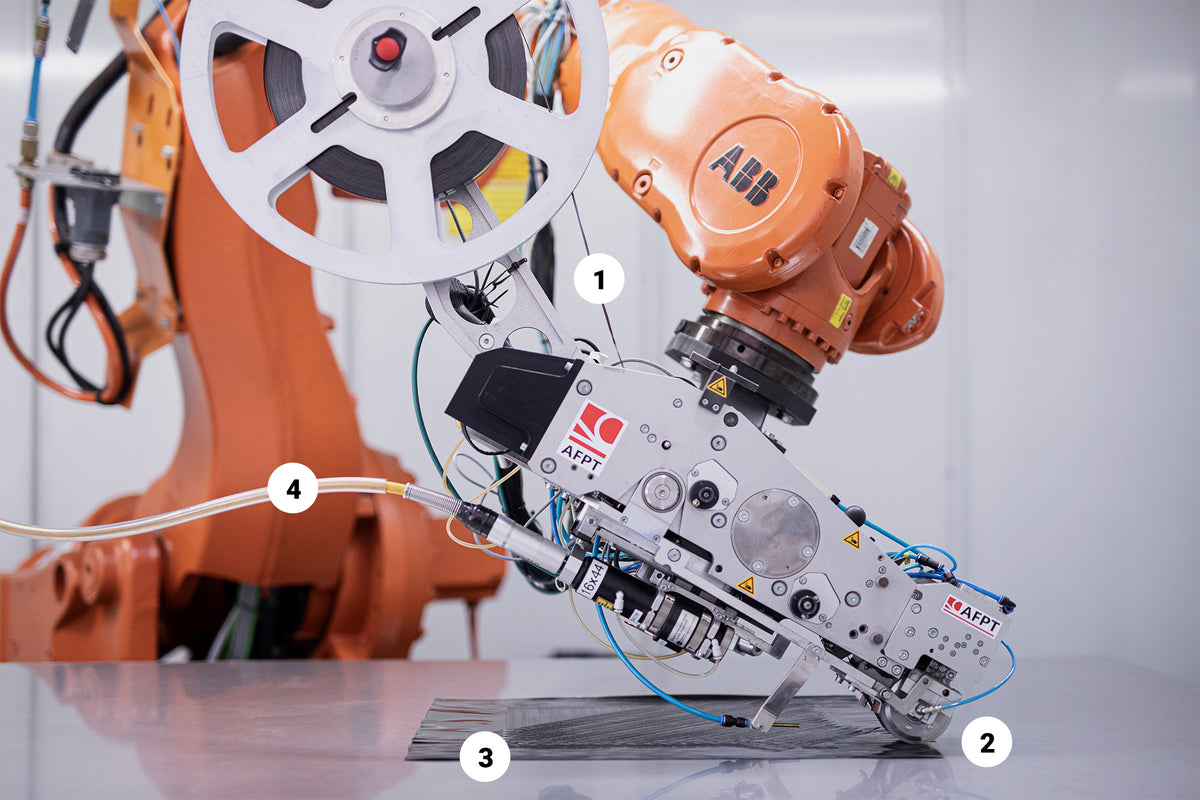

The UD tape material (typically 12 or 25 mm wide) is unwound and transported to the tip of the placement head (1). At this point, the laser system (4) locally heats the tape above its melting point. Immediately after heating, the tape is placed onto the mold or substrate (3) using the pressure-applying consolidation roller (2). All process parameters are logged for quality assurance purposes.

Discover the automated precision behind the Tape Placement process. Watch the video to see the process in action and witness how TAFNEX™ UD Tape is transformed into a tailored blank.